A black screen.

Having been stopped dead in my tracks by the black screen of despair, I stopped and had a long think about what to do next. I could throw the board in the bin after salvaging the custom chips etc. Or I could run around the room waving a ladle and screaming 'the transmission of the Austin Allegro is mounted transversely to reduce gyroscopic torque'.

Fortunately I decided to go back to basics.

Check the traces. Again.

First up, the 68000. As the screen is black and black normally means a dud processor, I did two things. I put in a spare good CPU but still got the black screen. Then I checked all of the traces from the 68000 out onto the board. No problems found.

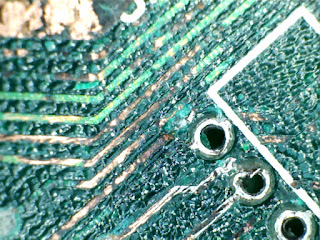

Next, I went back to the logic section. I tested all of the pins on U10. All traces good. Then U11 and 12. All traces good. Then, finally U13. All traces good BUT I noticed something that looked odd. A trace runs up to R111 (which was fine) and then from R111 to pin 25 of Gary. I measured this too expecting a resistance of 68 ohms. I got nothing. No continuity from the end of the resistor to pin 25.

This track is only about 5mm long so this was surprising and I was sure at some point I had checked this previously. Time to get a picture (or two)..

|

| Is that a break? |

After examining this I thought it was a straightforward break in the track. The green line through the trace looks like it is a break but this was a red herring and was actually a piece of the solder mask still in place.

Let's look a bit closer at the pad...

Let's look a bit closer at the pad...

|

| Well, there's your problem... |

Ah. That looks like a bit of an issue. The track has disappeared from the point at which it should join the pad. I suspect what has happened is that removing the temporary resistors that I previously installed defeated the few specks of copper that were left of this trace. A proper clean and new picture shows it a little more clearly. The dull circle around the edge of the solder is basically bare substrate.

To repair it I put a blob of solder on the leg of the resistor and dragged it across to the track. Relatively simple if not the neatest.

So, does this fix it?

NO. But we're now back to a green screen. This is the equivalent of getting the first 'chug' out of an ancient engine that's on the verge of starting for the first time in years..

After having another think about the basics again and, just for a laugh, I decided to re-seat all the chips including Agnus. Would you believe, as I removed Agnus, a chunk of corrosion fell out of the socket which was presumably accidentally inserted as I put the chip back into the new socket. A salutary lesson in keeping everything clean and tidy if ever there was one.

Back to the board. Does it power up and will it get past the green screen?

So there you have it. Another A500+ motherboard saved from the indignity of spare parts (or worse).

This board will eventually get a floppy drive and keyboard (and maybe an new expansion connector too) so I can test that it ALL actually works but, for now, I am overjoyed that I managed to get to the boot screen,

To everyone out there with an A500+ motherboard in this condition, keep at it. If I can do this, then so can you!

Here's a couple of pics of the success:

A list of parts used:

Resistors:

2 off 28 ohm 1/4 watt

1 off 47 ohm 1/4 watt

3 off 68 ohm 1/4 watt

2 off 1K ohm 1/4 watt

Capacitors

1 off 10nf ceramic disk (not quite as original but OK)

Chips

2 off 74LS244

2 off 74LS373

Sockets

4 off 20 pin DIP sockets

1 off 84 pin PLCC socket

3 off 36 pin sockets sacrificed for their pins for Gary and Paula (their loss will be remembered)

Misc

Lots of solder

About four inches of green wire wrap which I had lying around

Time

Lots but the total is irrelevant if I can keep bringing them back from the brink...

Thanks for reading.

|

| Track broken at pad - oh dear |

To repair it I put a blob of solder on the leg of the resistor and dragged it across to the track. Relatively simple if not the neatest.

|

| Track now present |

|

| New solder track close up |

So, does this fix it?

NO. But we're now back to a green screen. This is the equivalent of getting the first 'chug' out of an ancient engine that's on the verge of starting for the first time in years..

After having another think about the basics again and, just for a laugh, I decided to re-seat all the chips including Agnus. Would you believe, as I removed Agnus, a chunk of corrosion fell out of the socket which was presumably accidentally inserted as I put the chip back into the new socket. A salutary lesson in keeping everything clean and tidy if ever there was one.

Back to the board. Does it power up and will it get past the green screen?

So there you have it. Another A500+ motherboard saved from the indignity of spare parts (or worse).

This board will eventually get a floppy drive and keyboard (and maybe an new expansion connector too) so I can test that it ALL actually works but, for now, I am overjoyed that I managed to get to the boot screen,

To everyone out there with an A500+ motherboard in this condition, keep at it. If I can do this, then so can you!

Here's a couple of pics of the success:

|

| The recovering patient |

|

| The glorious purple screen |

Resistors:

2 off 28 ohm 1/4 watt

1 off 47 ohm 1/4 watt

3 off 68 ohm 1/4 watt

2 off 1K ohm 1/4 watt

Capacitors

1 off 10nf ceramic disk (not quite as original but OK)

Chips

2 off 74LS244

2 off 74LS373

Sockets

4 off 20 pin DIP sockets

1 off 84 pin PLCC socket

3 off 36 pin sockets sacrificed for their pins for Gary and Paula (their loss will be remembered)

Misc

Lots of solder

About four inches of green wire wrap which I had lying around

Time

Lots but the total is irrelevant if I can keep bringing them back from the brink...

Thanks for reading.