You'd think that after showing the Cifer some love it would appreciate not being in a skip and show a bit of gratitude. Sadly, it didn't for a couple of reasons. First, the RAM failed again. Second, it is not a corporeal being no matter how much I try to anthropomorphise it (but I know he's mocking me).

|

| Garbage! Argh! |

This is absolutely the same type of fault it had when it first arrived and, also more recently, when I tried to get him back up and running after he'd been lying on his side with his guts hanging out for about six months...

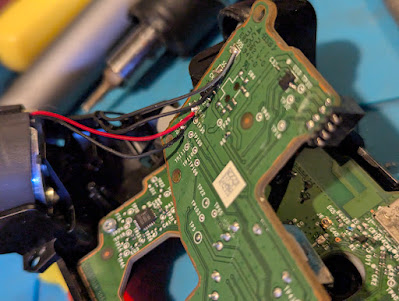

So, back into the depths. I removed the bottom cover, then the 68K board, the graphics board and the auxiliary board to reveal the main 'motherboard'. Thinking that it could be one of the other boards that had a RAM problem, I tried switching it on with just the main board installed but I still got the garbage on screen. This means that it is absolutely one (or more) of the eight RAM chips on this board. Darnit.

|

The offending RAM on the bottom right. Not an MT chip

in sight though. |

Out came the homemade RAM tester and every chip was tested. You can imagine how annoyed I was that every chip tested OK. Does this mean there's something else that has gone wrong? I hope not..

Digging through my Box'o'Bits(R), I found a couple of spare RAM chips that were not MT (I still don't know where they came from - some rotten *** sold them to me I think) with the idea to replace one chip at a time to see if all of those chips really were working.

With the 'new' chip in hand I replaced the first chip. No change. So I took the first chip and used it to replace the second. No change. Then I took the second chip and replaced the third and...

|

| It's alive! (Again - but for how long?) |

..that was it! The third chip I took out was faulty. Just to be sure I marked it and re-installed it and, sure enough, the garbage returned. Why the RAM tester did not highlight this chip as faulty I don't know. I thought I might have to go back and re-write the tester 'c' program that was installed on the Arduino clone that is the heart of the DRAM tester. The original version of the program is now, sadly, lost to a hard disk failure many years ago but I do have the code it was based on (or more accurately 'shamelessly copied from'). The big disadvantage of my tester, other than it seems to think a faulty chip is OK, is that it's really, really slow. It typically takes about 50 seconds to check one chip. Multiply that up and even testing a relatively small number of DRAMs can take some considerable time.

While wondering if there was any way to improve the code that I technically no longer had, I stumbled across a

YouTube video on a channel called 'Trevor Makes'. In this video he described exactly the issue that I had with the RAM from the Cifer i.e. my quick and dirty tester showed it as OK but, once installed, it was clearly faulty. His version of the DRAM tester takes a different approach and uses the 'March C-' algorithm to quickly check a DRAM.

I don't pretend to understand much about the March C- algorithm. A quick Google just highlighted the most basic of explanations - which comes down to "it's fast" - and a lot of technical documentation with odd notation that is clearly logic based. Suffice it to say that it's fast, and it carries out tests that cover all fault conditions on the chip (as per Trevor's video - code on his

github page).

Anyway, I decided to re-configure my current DRAM tester as it was clearly giving false positive results - could it also be giving false negatives? (Foreshadowing...ooooh!)

I shan't bore you with the details of re-wiring a circuit board. It's not a great spectator sport but, suffice it to say, I did it and I double checked it. Then I triple checked it. All connections were as per the diagram on the github page so all that was left to do was to reprogram the Nano clone that formed the brains of the outfit. And that was a where things went a bit wonky.

Programming an Arduino of whatever vintage/provenance can be done using the official Arduino software and this was what I had previously used with my DIY tester. This particular project though, is built using Platformio with Visual Studio Code. I'm reasonably familiar with VSC but I'd never used it for programming any type of embedded system before. Fortunately, Trevor Makes

has a video for that too and, after a little bit of head scratching (I had to change the default platform to 'oldnano'), I managed to get the code compiled and on to the tester.

First test, I put the faulty chip into the socket and plugged it in. Red LED lit almost instantly. OK so far. Then I put a known working DRAM chip into the tester (the MT4264 - don't judge me). The red LED lit almost instantly. Oh. That was unexpected. So then I went and got my small collection of working DRAMs. Every single one came up as faulty almost instantly. Something was not right.

I decided to check the address lines that were being used on the DRAM and I immediately found the problem. The lines A0 and A1, which connected to the D0(RX0) and D1(TX1) on the Nano, were both being held high. All the other address lines were showing the expected typical activity. So why are these two lines being held high? The answer was in the primary purpose of the pins i.e. RX0 and TX1. These pins are connected to the Nano's UART and, to use them for any other purpose than serial connections, requires that the serial device is disabled in the code. I am not an expert in programming C++ or Arduino, rather I am an enthusiastic amateur, so I have no idea if the switching off of the serial device was included in Trevor Makes' code. I knew I could at least try adding the code that Google's AI helpfully suggested, which would definitely switch the serial off in the 'initialisation' part of the code. And this, I duly did.

|

| Additional lines of code circled red. |

Another build cycle with the revised code was completed and after uploading the update firmware to the nano, I put the working MT RAM chip into the socket and switched the tester on. The first thing I saw is that all four LEDs on the Nano board itself lit up. This matched Trevor Makes' video which I took as a good sign. And then after a second or so the green LED lit up. Yes! This DRAM is, according to this new code, working.

|

| The light is green, the trap is clean. |

I set about testing the latest dead DRAM from the Cifer. Bear in mind that the old version of the tester said that this chip was fine and dandy but if it was in the Cifer, it would not boot. Within a second, the tester told me what I already knew. This DRAM was dead - the red LED lit up. Excellent. I tested all of my remaining known working DRAMs and they all came up green so I could fairly confident that this is now working as expected.

This version of the tester has a couple of major advantages over the old version. First, it's fast. It really is. A 4164 1 bit 64k RAM is tested in just over a second, while a 41256 1 bit 256k RAM takes about 4 seconds and it's intelligent enough to know which type is inserted (4164 or 41256). Secondly, there are two distinct modes that this test can use. There's the standard test mode which I'd been using up to that point, but there's also a timing test. By switching one of the Nano pins to ground, the firmware copies a checkerboard pattern into the chip and then cycles round, reading the data back in a loop. With a strategically connected two channel oscilloscope it's possible to calculate the access speed of the RAM - handy to check if second hand chips have been 'altered' to make them seem better than they actually are.

Just on a hunch, I pulled out a big batch of 'failed' Hitachi RAM from the 68K board in the Cifer. Out of 15 alleged failed chips, 13 chips tested OK. I need to validate this somehow and it might end up with my taking a couple of the apparently working chips and throwing them into the Cifer to see if they really are OK.

|

| 13no DRAM chips tested OK. Hmmm. |

But now, with a vastly improved DRAM tester, I can go and check every RAM chip that is in the Cifer. RAM appears on the main board, the auxiliary board and the graphics board, and so there's plenty to go at.

While I was at it, I 3D printed a new version of the rather basic case. My latest filament is Amiga beige but it'll do. I also added an 'on/off' switch since I also decided to add a fixed USB cable to drive the tester. Very handy. The power switch is the one at the bottom and the 'mode' switch is at the top. These were the only switches I could find in my Box'o'Bits(R) but they work fine.

|

"New case, who 'dis?"

|

Interestingly, I checked the 8 RAM chips on the Cifer graphics board (Tetronix 4010 emulation) and, would you believe it, one of the chips tested faulty. The auxiliary board has 32 RAM chips so that will have to wait until I have a little more spare time.

|

Last act of defiance - adding an MT RAM chip

back IN to a vintage computer. Sue me. |

|

| So many RAM chips, so little time... |

And there you go. I'm very pleased with the updated DRAM tester and even more pleased I didn't throw away all those chips that the old tester claimed were faulty. Nice.